HempTrain™

The HempTrain™ Advanced Processing System is a state-of-the-art technology, developed by our award-winning engineering group (since 1987) to process, non-destructively and automatically, baled hemp straw (round or square bales, any size) into high value long, strong fiber, spec-sized hurd and nutrient rich, green biomass microfiber. HempTrain™ is offered as a turn-key facility, including delivery, installation and commissioning as well as training. The facility comes with a 2 year warranty.

After success of the first commercial model launched in 2018, we have launched the 2023 Model with substantial upgrades;

-

-

Increased throughput to 3000 lbs per hour with much enlarged facility

-

Processing of high Fiber content feedstock upgrading kinematics, enlarging processors and upgrading process with anti jamming controls - to produce high quality long strong fiber

-

Fiber cleaning capacity adding Fiber cleaning modules with special kinematics and controls

-

Creating one more product stream - fine hurd

-

Automatic strapping of fiber bales

-

Contact us to book your demonstration tour of a HempTrain™ Advanced Processing Plant or take a virtual tour!

Equipment Specifications

Throughput: Up to 3000 lbs/hr (feedstock-dependent**)

Area Required: <2200 sqft

Machine Height: ~16′ (5 m) (~19′ needed for installation)

Machine Weight: ~90,000 lbs

Bale Window Opening: 5’ x 6′ (1.6m x 1.8m). Some bale configurations may require operators' involvement in bale loading.

Hurd Fiber Particle Length: From 1/8" (3mm) to 2" (50mm)

Power Requirements: 175 kVA, 480V, 3-Phase

**Certain types of feedstock with a higher content of bast fiber (>15% w/w) and longer bast fiber in length (>3ft), as well as certain bale configurations may significantly affect the throughput capacity. Feed rate and manner of loading may change significantly depending on feedstock.

Features

HempTrain™ Baled Straw Opener

The HempTrain™ Baled Straw Opener is the only system in the world that has been engineered to non-destructively open (mass-process) baled hemp straw, square or round bales on an industrial scale.

The HempTrain™ Baled Straw Opener, unlike conventional unwinders, has been engineered specifically for industrial hemp. Its innovative design allows it to withstand the unique rigours of long, high tensile strength hemp fiber (avoiding wrapping and clumping) without damage to the fiber. It is also, very importantly, engineered to minimize the destruction and loss green material, and the bio-nutrients it contains while ensuring the hemp remains intact, structural, and undamaged to be further processed into high-value products. With an operational window of 5' x 6' (1.6m x 1.8m), the HempTrain™ Baled Straw Opener does not require any alignment of hemp stalks to separate.

High Kinematics Decorticator

Our patented decortication technology allows hemp stalk separation without any destructive action, producing long intact fiber and clean hurd. Unlike conventional decortication technologies, HempTrain™ decortication does not destroy the integrity of fiber or hurd and does not create any dust.

Fiber Cleaner

Our proprietary modular Fiber Cleaner allows removal of majority of hurd remaining after decortication from the fiber, thus creating a cleaner fiber and recovering more hurd.

Note that some applications may still require final fiber cleaning which would involve some special machinery not supplied here.

Hurd Refiner and Sizer

Our patented Hurd Refiner and Sizer is the only such machinery in the hemp industry, processing decorticated hurd ito clean spec-sized hurd.

Fiber Products Baler or Packaging Unit

The bast fiber baler will compress fiber into 14"x18"x36" bales, each 5.25 cubic foot bale produced is roughly 45lbs and expands to 9 cubic feet.

The bast fiber packing unit will compress fiber into 12"x12"x16" bales. These bales can be strapped (with an included automatic strapper or packaged into bags and heat sealed with the included heat sealer.

Explosion Controlled Dust Control System

The HempTrain™ facility is provided with an engineered, American built dust control system that is designed specifically for hemp dust. This system has integrated fire containment and explosion suppression. It is meant to be installed indoors, which means no additional make up air is required for the space.

Additional Machinery

Hurd Products Compression Bagger

Model CGT-Hurd Bagger

Hydraulic compression bagging machine is capable of compressing hurd 2:1. The finished, compressed bag size is 12” x 9” x 17” (approximately 65 litres uncompressed, 15 lbs/6.8 kg, feedstock dependent) These bags are heat sealed using the included heat sealer.

Watch the Compression Bagger in Action!

Operation

What is the HempTrain™ Advanced Processing System?

Demonstration- How Does A HempTrain™ Operate?

*Certain types of feedstock with a higher content of bast fiber (>15% w/w) and longer bast fiber in length (>3ft), as well as certain bale configurations may significantly affect the throughput capacity. Feed rate and manner of loading may change significantly depending on feedstock. For more information, please contact us.

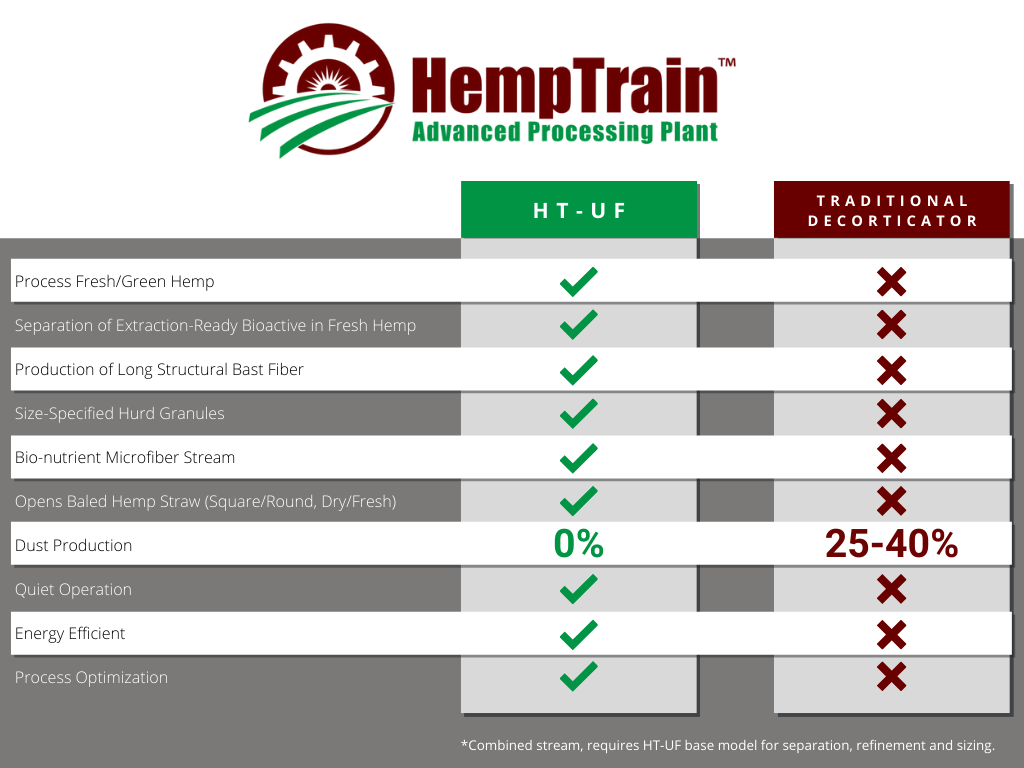

Conventional decorticators (hammer mills, scutchers, etc.) use technology that is, in some cases, over a century old. These mechanisms were designed for destruction of their feedstock, damaging the hemp and causing attrition to both bast and hurd fibers. This destructive action leads to a loss in fiber integrity, and bast fiber cannot therefore be used effectively in contemporary reinforcement applications. This action also reduces the size of all feedstock components, creating a mixture that cannot be then separated into its constituents efficiently or cost-effectively.

The HempTrain™ Advanced Hemp Processing System employs a unique and proprietary decortication mechanism, that can non-destructively separate long bast fiber from the stalk core.