Published January 25, 2019 | Updated December 12, 2019

Hemp Processing Technologies

A surge in growth in the US hemp industry creates new demand for specialized processing facilities.

With the 2018 US Farm Bill (Agricultural Improvement Act of 2018) now in effect, the US is now permitted to grow industrial hemp (after an 81-year ban). With this new opportunity, there has been a surge in demand for specialized hemp processing facilities.

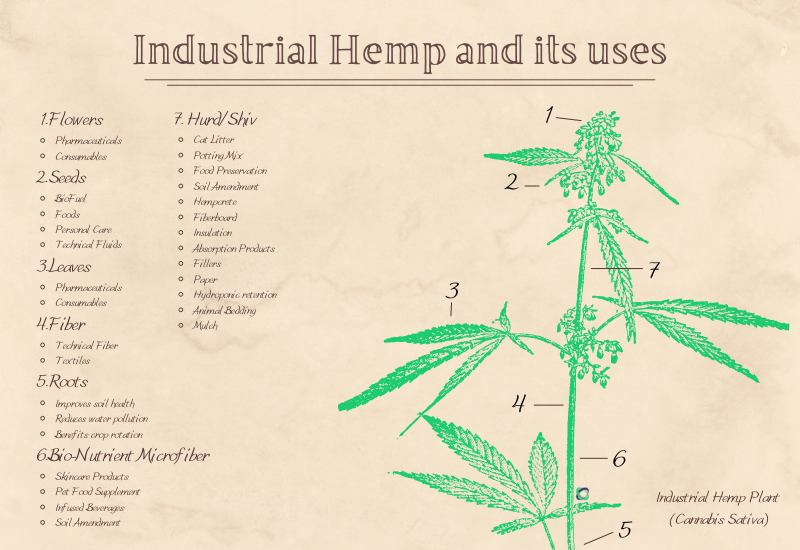

While hemp seed is a commodity product, alternative and/or additional revenue streams can be achieved from the waste hemp stalk. With the correct technological infrastructure, the entire hemp field can be harvested and converted into high-value products, for sale domestically and internationally. One of the most valuable derivatives of industrial hemp is CBD. This market is projected to dwarf the CBD from the marijuana market within only a few years. Without advanced hemp processing technologies for converting the whole hemp plant into value products, there can be no industrial hemp industry.

Decortication

Decortication is the separation of hemp’s outer layer (bast fiber) from the inner core (hurd). Current decortication uses the same hammer mill or hammer mill-like mechanisms (rollers, scutchers, etc.) that have been used for over a hundred years; which uses a beating action to break down hurd and fiber, significantly damaging both while creating a substantial amount of dust. This damage is a severe limitation of conventional decortication technologies, limiting the hemp fiber produced to low-value markets.

The state-of-the-art kinematic mechanism employed by the HempTrain™ Advanced Hemp Processing Plant does more than just decortication and is far less damaging to the fibers and hurd; creating no appreciable dust. The products produced by HempTrain™ can be used in high-value markets such as fiber reinforcement, consumer products, and CBD-derived from industrial hemp.

The Future of Hemp Processing

The HempTrain™ Advanced Hemp Processing Plant is a complete hemp processing solution, bringing new technological innovation and market potential to the industrial hemp industry. HempTrain™ separates whole hemp plants into high-value products for readily accessible high-value markets.

HempTrain™ is capable of processing both fresh/green and dry hemp. When processing fresh/green hemp, HempTrain™ will produce a high-CBD extraction-ready fraction; the only technology capable of doing this on an industrial scale.

When processing dry feedstock, HempTrain™ converts the entire hemp plant into three high-value product streams: green microfiber, long, structural bast fiber, and size-specified hurd. Green microfiber is rich in bio-nutrients such as cannabinoids, terpenes, and protein, and can be used in various high-value applications from hemp-infused food and beverages to cosmetics. Long, structural bast fiber can be used for the high tensile strength required by engineered materials. Hurd, clean and sizeable, can be used everywhere from cat litter to food preservation; high-value markets requiring cleanliness and size-specificity.

The HempTrain™ Advanced Processing Plant uses proprietary technologies, developed by Canadian Greenfield Technologies, and creates unique, high-value products not available from conventional decortication technologies (hammer mills, field decorticators, scutchers, gins, etc.). Furthermore, HempTrain™ creates almost no dust or waste products, enabling true whole plant utilization.

HempTrain™ is the Future of Hemp Processing

*Certain types of feedstock with a higher content of bast fiber (>15% w/w) and longer bast fiber in length (>3ft), as well as certain bale configurations may significantly affect the throughput capacity. Feed rate and manner of loading may change significantly depending on feedstock. For more information, please contact us.

Want to Know More About the Future of Hemp Processing? Check Out These Links:

- HempTrain™ Specifications

- HempTrain™ FAQ

- HempTrain™ on BNN

- HempTrain™ & CBD Production Efficiencies- Whitepaper

- HempTrain™ & Fresh/Green CBD Efficiencies- Whitepaper

- USA & Canadian Legislators Tour HempTrain™ Facility

About Canadian Greenfield Technologies Corp.

CGT is an award-winning Calgary-based engineering & manufacturing company specializing in hemp products and processing technologies. An off-shoot of an international-award-winning industry group in business since 1987, CGT is an industry leader with unparalleled expertise in hemp processing and the only supplier of complete whole-plant hemp processing facilities in North America, having developed, designed, engineered, and manufactured the state-of-the-art HempTrain™ Advanced Processing Plant.

Stay tuned for updates. Follow Canadian Greenfield Technologies on Facebook, Twitter, Instagram and LinkedIn. For videos on real-world applications of hemp products, demonstrations, and ground-breaking technologies, subscribe to CGT’s YouTube Channel.